Cylinder Head

Development

We specialise in the development and production of gas flowed cylinder heads for most modern and classic engines. Aimed mainly at racing, we offer for many V8 and V6 engines. Also Duratec, Zetec and XE variants.

All our gas flowed cylinder heads are precisely manufactured for maximum efficiency and performance. We invest extensively in developing the very best possible head. We measure the flow precisely and test power output on our own engine dynometer. We are proud of our results and publish the flow figures for each head. Using our scanning technology and CNC engineering machines we are able to replicate our high performance optimum design. This technology enables us to predict the potential horsepower gains made possible by fitting the head to your engine.

Why are Valve Guides important?

The valve guide is the boundary layer point between the head and valve. Proper valve guide material and design will effect many aspects of the engines operation. Firstly, if the valve is loose within the guide, this will effect the valve and seats ability to seal the expanding gasses. Secondly, material choice is very important, most if not all guides fitted to engines from Rover to Ferrari have cast guides.

The problem is that these guides when cast have tiny gas bubbles in them called porosities. Each guide can react differently under varying degrees of heat exposure experienced under engine operation. In one guide for instance, this could cause the guide to become slightly slack in the cylinder head. Within another guide, the valve could be a little loose. Although these may not be felt in engine operation or they may. But these are the very variables we must avoid in the search for performance increases and more importantly, performance consistency and reliability. This is why specialist alloys that have far more consistent material density and thermal reaction, such as COLSIBRO, are implemented in the construction of these guides.

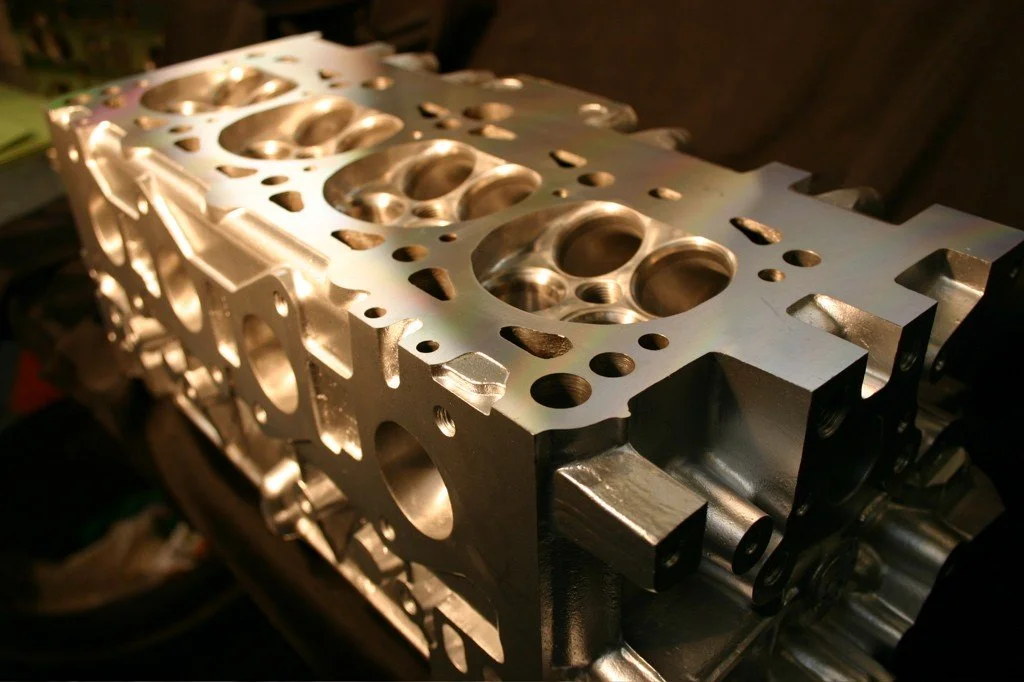

We manufacture to incredible accuracy using the latest CNC technology which ensures each head produced is identical and each cylinder in the head performs the same as the others in the engine. The major benefit to you is performance, cost and quality. Properly gas flowing and modifying a head is very time consuming and hence very expensive. We optimise one head type once then scan and replicate the design exactly. The results are identical to the original modified head but the cost is very much less.

“Gas flowing” involves re-profiling of the inlet and exhaust ports in the cylinder head to allow the fuel/air mix to flow in and the exhaust gases to flow out more efficiently. Essentially it is a redesign of the port based on extremely accurate measurement of size and flow rates and how changes to the port affect the flow.

Of course, hidden behind the word “redesign” is a great deal of detail and pure experience of what works and what doesn’t. What is too much and what is not enough. This development process relies heavily on the experience of the expert doing the job and the measurement tools available to him.

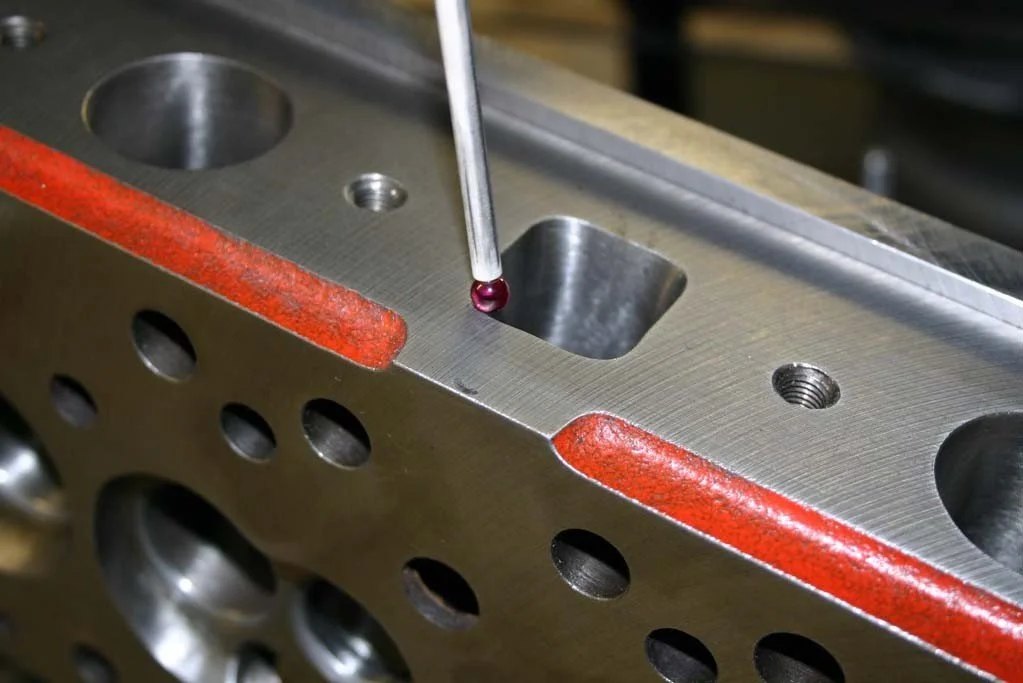

The development process of a new head starts with a base line measurement of the standard head. The gas flow engineer then begins to modify that port by identifying possible points which could be modified by removing material and changing the surface finish and then making that change by hand using accurate hand controlled tools. This can only be done using experience (in our case over 20 years of experience). It is entirely possible to make changes that do not work or break through the head material to the water cooling circuit during development. Sometimes we have to scrap a head and start again. Knowing what works and what doesn’t is where “experience” comes in.

The changes he makes can then be measured and a further cycle of modification and measurement is carried out until gas flow improvements (accurately measured) reach a point where the head can be said to be optimised (within the parameters of the head design, valve size and lift). The process is iterative and very analytical. Very subtle changes in the port make a large difference to the CFM measurement. To assist in achieving the optimum design, we use the latest gas flow bench and software to measure and record changes.

Changes we make are mainly achieved by removing material from the head which changes the shape and dynamics of the flow through the port. Some tuning shops add material (by welding or using epoxy resins) to the port to change its shape. However, although this is a valid modification in terms of flow improvement, most race series do not allow adding material to the port profile.

Our heads are mainly aimed at racing and hence we do not add material to the port. They are fully legal for most competition uses. Power improvements at the ‘cutting edge’ of racing come from minor improvement in details. For cylinder heads, these details not only include flow, but port velocity, swirl and tumble motion.

The Port Flow Analyzer software we use has options for port velocity mapping with a pilot tube, swirl and tumble measurement (using our swirl meter and our tumble adapter), fort stability, etc. Using these features and the processing power of the computer (and some fairly advanced physics contained within) we are able to predict the potential power of an engine fitted with this head from the flow bench! This power prediction is amazingly accurate to within 1% and has been verified on our engine dyno.

CUSTOM APPLICATIONS

As well as providing our ‘standard’ range of heads we also provide custom engineering services. We can gas flow any modern or classic head. We can replicate a head which is known to work well using our scanning facilities. We can also replicate a damaged head to exactly the same spec as original.

OUR PRODUCT CATALOGUE

We have a growing catalogue of gas flowed heads suitable for circuit racing, rallying or street use. We have a wide range of Ford and GM heads. These heads are used on our own race engines. We publish all our gas flow figures as they are measured from the flow bench. With CNC engineering we guarantee accurate and consistent flow figures across all cylinders and on every head. You get exactly the same flow we got on our final prototype head.